Offshore Equipment & Cranes

High-performance offshore equipment engineered for mooring, positioning, and safe, efficient marine handling operations.

Mooring Systems

Mooring Systems

A mooring positioning system is used to anchor and stabilize offshore floating structures or vessels within a designated sea area. It limits the impact of external forces—such as wind, waves, and currents—to keep the vessel or platform in a fixed position. These systems are essential for offshore operations, including drilling platforms and ships.

Mooring systems can be categorized by duration and configuration.

By duration: short-term or long-term mooring positioning

By setup: single-point, two-point, or multi-point mooring systems

Each type is selected based on operational needs, environmental conditions, and vessel specifications.

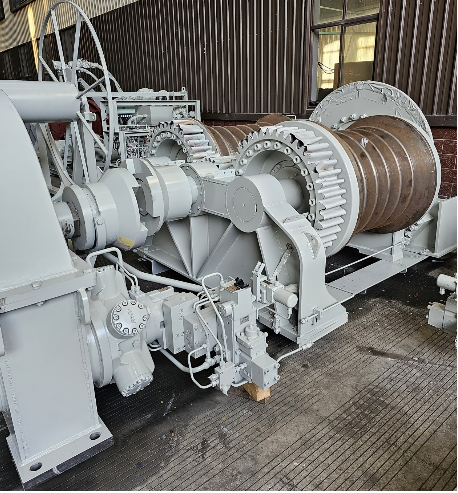

80T Offshore Positioning Winch

Main Parameter

Drum capacity: 800m@®90mm

Rated Pull:

800KN@12m/min (middle layer)

Supported load:

5650KN (second layer)

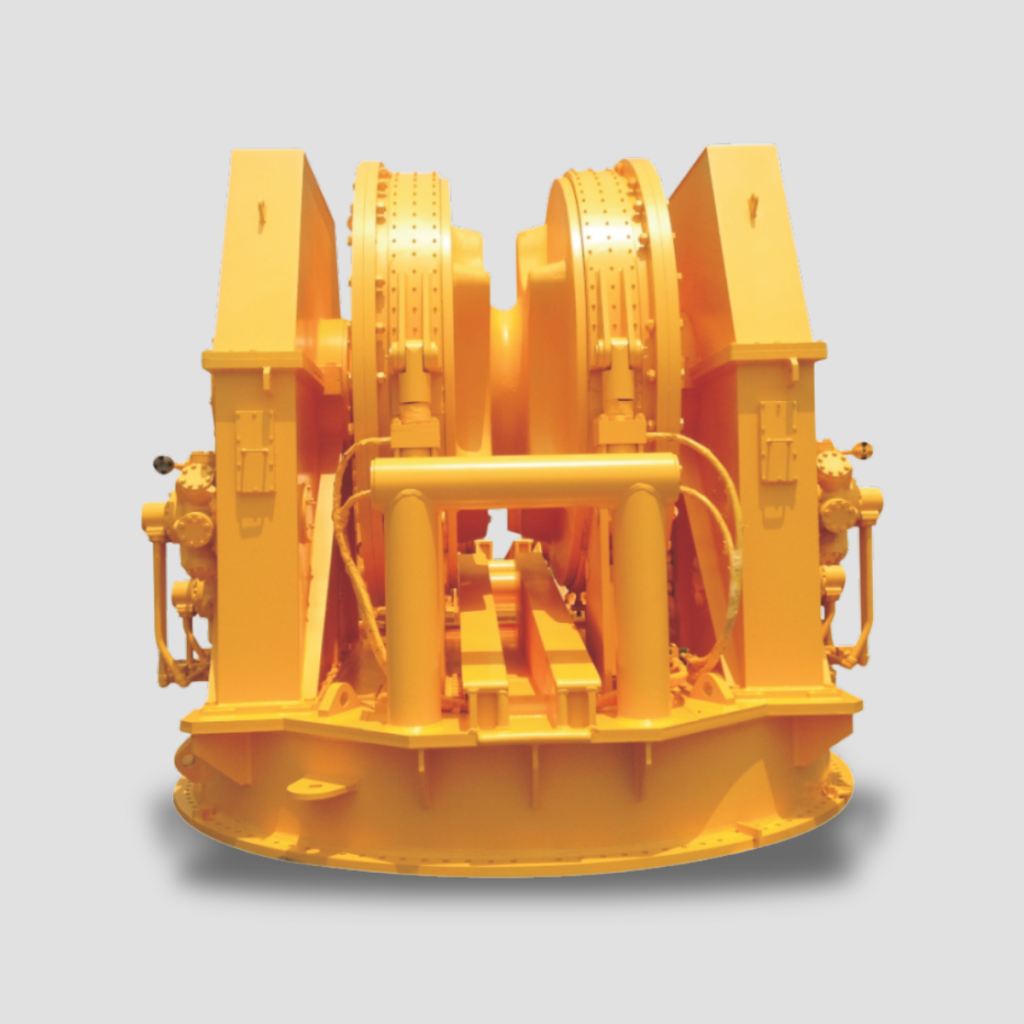

132mm Offshore Positioning Windlass

Main Parameter

Chain Diameter: ®132mm

Rated Pull: 1500KN@15m/min

Marine Cranes

Offshore cranes are essential equipment on marine engineering vessels and platforms, used for loading, unloading cargo, and lifting personnel at sea. As critical tools for both production and safety, they must meet high standards for safety, reliability, maintainability, wind resistance, and corrosion protection.

These cranes feature large lifting capacities, smooth operation, impact resistance, strong braking performance, and high cargo handling efficiency, making them highly adaptable to a wide range of offshore tasks.

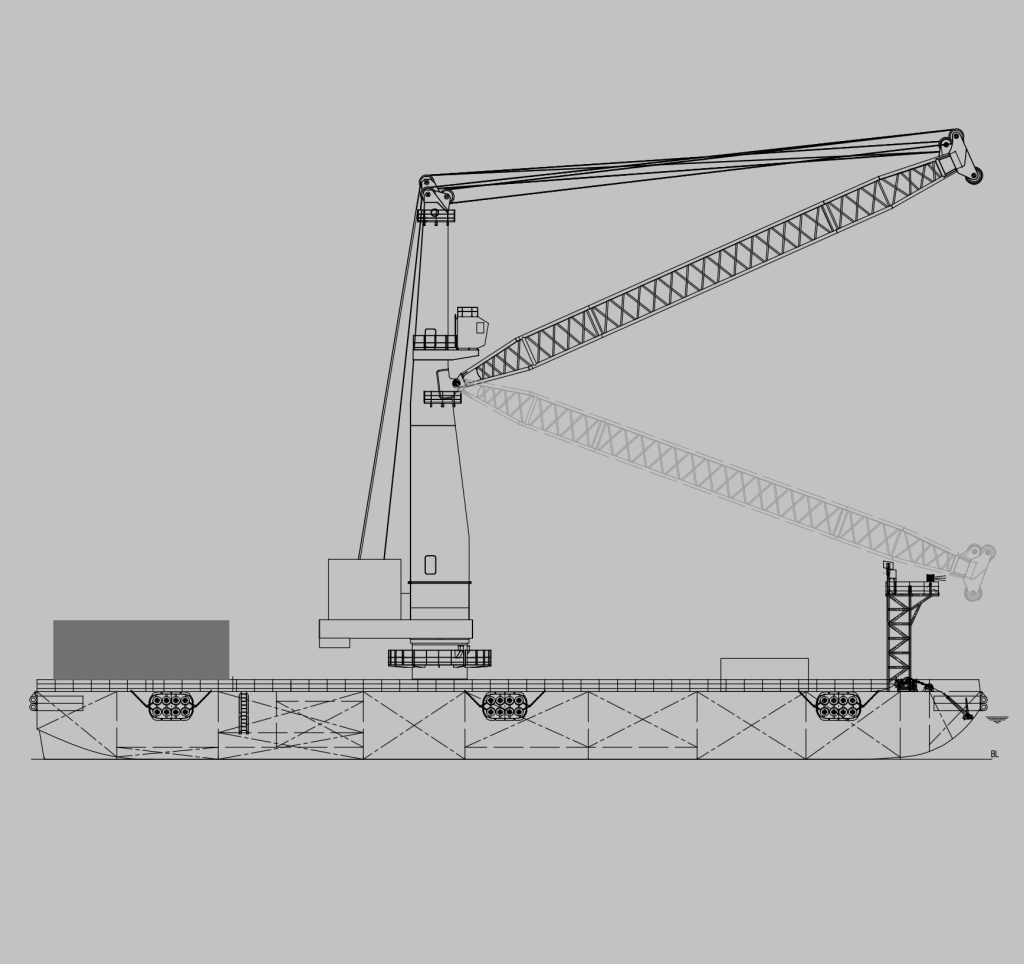

Barge Cranes

Barge cranes are versatile lifting systems designed for loading and unloading operations between ship and shore, or between vessels. Their lightweight design, low center of gravity, and excellent stability allow for smooth and flexible rotation.

Equipped with hooks or grabs, they offer large lifting capacity, easy operation, strong impact resistance, and high cargo handling efficiency. Built for demanding marine environments, barge cranes are engineered for safety, reliability, maintainability, wind resistance, and corrosion resistance.

*NEW* Bow Loading System

Discover the Masada Bow Loading System (BLS), revolutionizing the safe and efficient loading of oil from offshore production or storage facilities, including Floating Production Storage and Offloading (FPSO) installations, by shuttle tankers.

A next-generation maritime solution that stands at the forefront of cutting-edge technology. Meticulously engineered with precision, this innovative system redefines industry standards, promising unparalleled efficiency and reliability in vessel loading operations.

Hose Handling System

A complete offshore loading solution featuring a 20-inch bow-loading coupler and inboard valve. The coupler connects to the end valve of the loading hose from an FPSO, FSO, or offloading platform, while the inboard valve controls the flow within the loading line. The system also includes key accessories such as a hose winch, bow door, and slipway for safe and efficient hose deployment and retrieval.

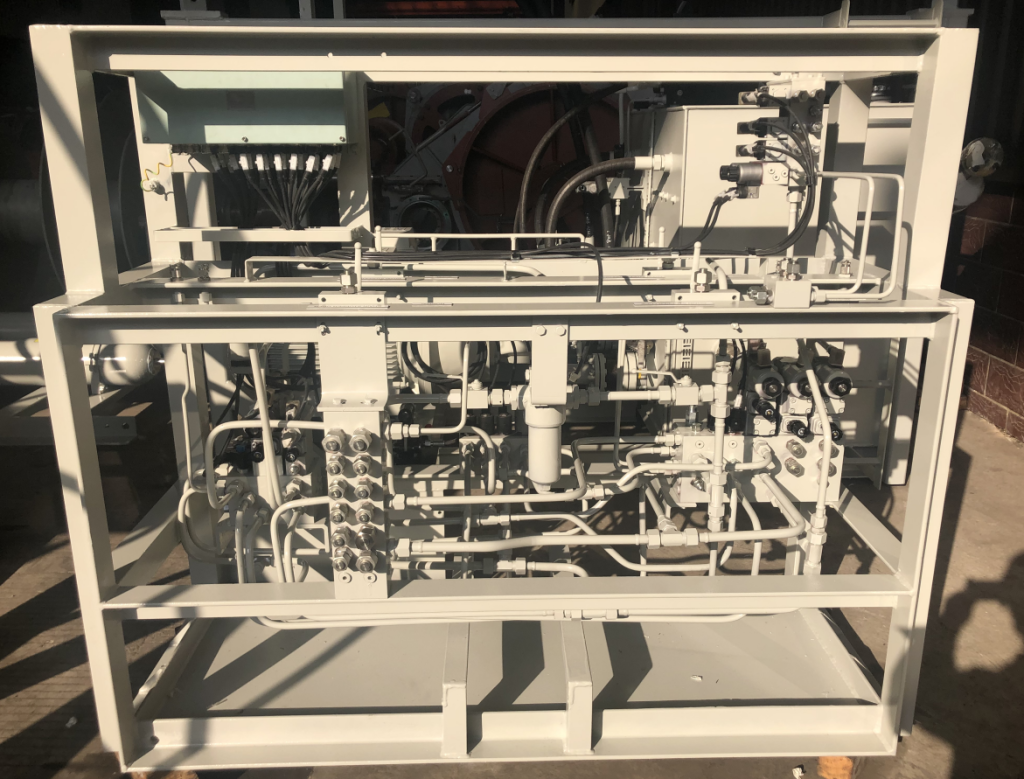

Single Point Mooring System

The SPM system is designed for tandem loading operations and includes an adjustable roller fairlead, hydraulically operated self-locking chain stopper, and a twin-drum traction winch.

The chain stopper can be released under full load, while a rope storage winch complements the traction system. A built-in load cell within the guide roller at the rear of the chain stopper enables precise load monitoring during mooring.

Operating and Control System

The BLS system is hydraulically operated, with explosion-proof components installed based on specific location requirements. It includes both a standard operation system and an emergency release system to ensure safe and reliable control under all conditions.